When preparing documents for office work, academic assignments, product packaging design, or print-ready marketing materials, you’re likely to encounter the term “collate.” Many people ask, “What does ‘collate’ mean when printing?”—especially when printing large batches of multi-page documents. Understanding this term is crucial for ensuring your documents appear in the correct sequence, look professional, and save you valuable time.

In this in-depth guide, we’ll explore what collating is, why it matters, when to choose collated vs uncollated, and how it connects to packaging, product dimensions, and even everyday items like cigarette packs, milk cartons, and shoe boxes. You’ll also learn how collating plays a role before packaging products inside printed containers—whether that’s a table lamp packaging box, stevia packaging, or even the largest cardboard box used in warehouses.

What Does “Collate” Mean When Printing?

So, what does “collate” mean when printing?

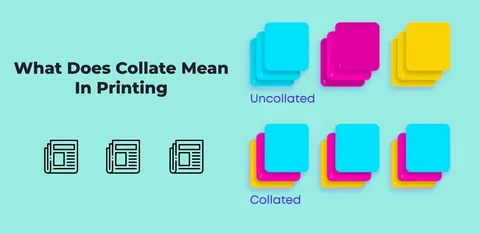

In printing, to collate means to arrange printed pages in the correct, sequential order, especially in multi-page documents.

For example:

- Collated printing produces:

Page 1 → Page 2 → Page 3 → Page 4 (complete set)

Then repeats that full set again. - Uncollated printing produces:

All Page 1 copies together → all Page 2 copies together → all Page 3 copies together, and so on.

When you print a 20-page report for several people, collating ensures each set is printed in the correct order without manual sorting.

This function becomes essential when printing booklets, manuals, catalogs, or anything that requires assembling pages properly—especially during packaging workflows involving boxes of different dimensions like length x width x height, height x length x width, or custom cardstock inserts.

Why Collation Matters in Modern Printing

Saves Time and Eliminates Manual Sorting

Imagine printing 100 manuals with 30 pages each. If you choose uncollated prints, you’d have to manually arrange them, page by page. Collated printing saves countless hours and ensures consistency.

Ensures Professional Presentation

Businesses shipping products in standard packaging sizes—like milk carton sizes, shoe box size, 10x10x10 boxes, or nike shoe box dimensions—often include instruction manuals or promotional pamphlets. Collated printing ensures these inserts look polished.

H3: Essential in Packaging and Manufacturing

Collated manuals or inserts are commonly packed into:

- Stevia packaging boxes

- Table lamp packaging box designs

- Milk cartons

- The largest cardboard box in warehouse logistics

When printing inserts, collating ensures the correct sequence before they go inside any packaging container, whether it’s large or compact like a Marlboro box or carton of Newports.

Collated vs. Uncollated—What’s the Difference?

Understanding the difference helps you choose the right option for your print job.

Collated Printing

Collated printing arranges complete sets in order:

1 → 2 → 3 → 4

1 → 2 → 3 → 4

1 → 2 → 3 → 4

Best for:

- Booklets

- Manuals

- Training guides

- Reports

- Catalogs

Uncollated Printing

Uncollated printing groups identical pages together:

1 → 1 → 1 → 1

2 → 2 → 2 → 2

3 → 3 → 3 → 3

Best for:

- Flyers

- Handouts

- Repeated single-page documents

Choosing the correct option improves efficiency and reduces post-print handling.

How Collation Relates to Packaging, Dimensions, and Product Quantities

This article includes several keywords related to packaging sizes, dimensions, and even cigarette packs. These terms may seem unrelated at first glance, but they connect through print and packaging processes, where collated documentation often accompanies prepared goods.

Below is how these topics connect.

Dimensions Matter—Length, Width, and Height in Packaging

Manufacturers and designers work with precise length, width, and height, also known as length x width x height measurements. These determine what fits inside a package—especially printed materials.

For example:

- A shoe box size must accommodate instruction sheets or warranty cards.

- A milk carton might include printed nutritional inserts.

- A 10x10x10 box could hold pamphlets or product kits needing collated documents.

Whether dealing with length and width only or full three-dimensional measurements like height length width, packaging requires accurate planning and perfectly sized printouts—further emphasizing the role of collated printing.

Cigarette Packaging—Why These Keywords Relate to Printing

Terms like

- how many cigarettes in a pack

- cigarettes in pack

- how many smokes in a pack

- how many cigarettes in a packet

- how many cigarettes come in a pack

- how many cigarettes are in a pack

- How many packets of cigarettes

- carton of marlboro reds

- carton of newports

- how many packs in a carton

- how many packs in a carton of cigarettes

- how many cigarettes in a carton

- how many boxes of cigarettes in a carton

All relate to packaging and printing standards.

Most cigarette packs worldwide contain:

- 20 cigarettes per pack (standard)

- 10 packs in a carton

- 200 cigarettes in a carton

When designing cigarette packaging, collated print materials may include:

- Warning labels

- Inserts

- Tax information

- Promotional slips

Whether creating a Marlboro box, milk cartons, or nicotine product cases, accurate print sequencing matters.

Even pricing questions like:

- how much is a pack of skydancers

connect to packaging, printing, and supply chain management.

The Role of Collation in Box Manufacturing

Packaging companies require accurate print sequences before gluing, folding, and assembling boxes.

Examples of Packaging That May Include Collated Prints

- Largest cardboard box for warehouse storage

- Stevia packaging for food products

- Table lamp packaging box for fragile electronics

- Nike shoe box for retail

- Standard milk cartons

- Custom retail cartons

Print instructions, warranties, manuals, and product info sheets must be collated to fit perfectly and appear in order.

Collation and Premium Materials — Why It Matters

When working with premium packaging materials—rigid boxes, specialty cardstock, laminated cartons—collation ensures:

- High-end presentation

- Accurate assembly

- Quality consistency

- Efficiency in mass production

Premium cardstock used for custom boxes often includes collated printed inserts, ensuring the brand’s customer experience is flawless and professional.

Even companies like buycustombox rely on precise printing workflows to deliver consistent quality.

When Should You Use Collated Printing?

Choose Collated When:

- Your document has multiple pages

- You need complete sets for distribution

- You’re printing manuals or product instructions

- You want to avoid manually sorting pages

- Inserts must go inside packaging in order

Choose Uncollated When:

- Printing bulk single-page flyers

- Distributing identical one-page sheets

- Manually assembling varied packets later

Common Examples Where Collating Is Critical

Product Packaging Inserts

Instruction manuals for:

- Shoes

- Electronics

- Home goods

- Beauty products

- Kitchen tools

All require proper collation before packaging.

Corporate Printing

- Employee handbooks

- Training modules

- HR booklets

Educational Printing

- Workbooks

- Student packets

- Multi-chapter documents

Collating in Digital vs. Offset Printing

Digital Printing

Most modern digital printers automatically collate pages.

Ideal for small to medium print runs.

Offset Printing

Used for large-volume runs; collation may require finishing equipment to assemble pages post-print.

How to Enable Collation on Your Printer

- Open your print dialog box.

- Select the number of copies.

- Check the box labeled “Collate” (often shown with three stacked page icons).

- If you want uncollated, uncheck that option.

- Choose print quality, paper size, and orientation.

Simple—but essential for accurate document production.

FAQs—What Does “Collate” Mean When Printing?

1. What does “collate” mean when printing?

It means arranging printed pages into correct, ordered sets.

2. What is the difference between collated and uncollated?

Collated = complete sets in order;

Uncollated = grouped identical pages.

3. Do I need collated printing for a single-page document?

No. It only applies to multi-page prints.

4. Does collating cost extra?

Usually no, especially on home or digital printers.

5. When should I choose uncollated printing?

When printing flyers or distributing identical sheets.

6. Is collating automatic on most printers?

Yes. Most modern printers handle it automatically.

7. Can collated printing help in packaging workflows?

Absolutely. Many products include collated inserts inside boxes.

Conclusion

Understanding what does collate mean when printing makes you more efficient when preparing documents, designing packaging, or printing instructions for products. Whether you’re handling manuals for table lamp packaging, inserts for milk cartons, or premium prints for the largest cardboard box shipments, proper collation ensures professionalism and consistency.

From packaging dimensions like length, width, and height to everyday items such as how many cigarettes in a pack or how many packs in a carton of cigarettes, printing plays a vital role in product presentation and manufacturing. And with premium materials becoming more common, accurate collated printing remains a cornerstone of quality.

If you’re working with printed boxes, manuals, or packaging materials, choosing the right collation settings can save time, improve quality, and eliminate errors—making your entire process smoother and more professional.

Let me know if you’d like a shorter version, metadata, an SEO title, or a featured snippet!